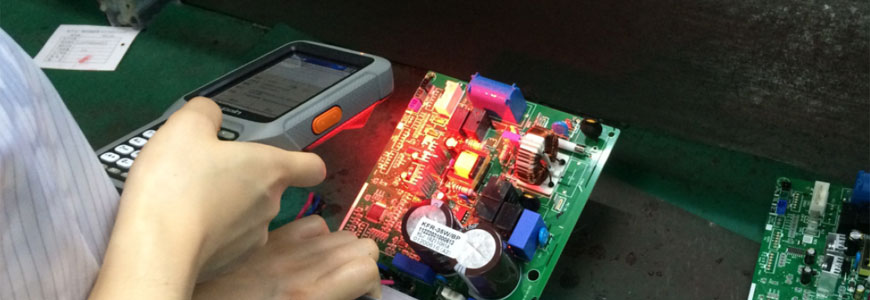

Electronic product traceability solution

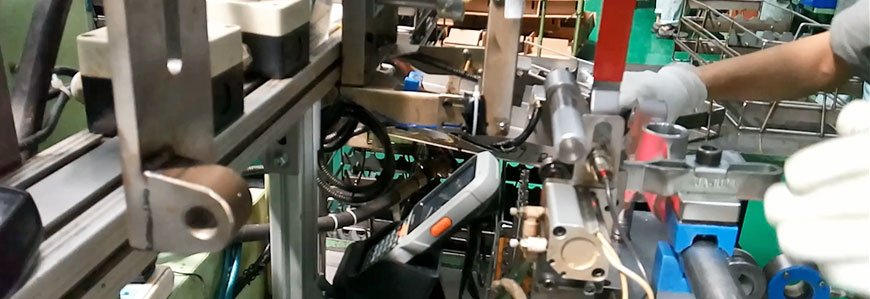

Through the use of Yanzeo DPM mobile smart terminal, real-time supervision and monitoring of the company's parts production and circulation links, and further optimize internal operation management. Industry pain points1. The PCB parts of the production line use laser engraving codes, which are difficult to scan in all links of ordinary mobile terminals;2. In terms of channel management, the fleeing of goods among various agents is serious and cannot be effectively monitored;3. The general warehouse and agent often make mistakes when shipping, resulting in inaccurate inventory;4. The production line and warehouse are inefficient in and out of the warehouse, which affects the delivery time;5. In the production line operation, employees adopt piece-rate management, and the operation efficiency directly affects piece-rate wages and reduces the enthusiasm of employees. Solution value1. Pinbang professional DPM handheld terminal reads all kinds of laser engraving codes, which is sensitive, fast and accurate;2. Improve the efficiency of the management process of all aspects of the enterprise and improve the accuracy of data.